The concept of coal pulverization stems from the belief that if the coal is made fine enough, it will burn almost as easily and efficiently as a gas. The raw coal is fed into the pulverizer along with heated air. As the coal gets crushed, the hot air dries it and blows the usable fine coal powder out, which thereafter is transported to coal bunker for storage or directly for use in blast furnace. The exhaust air is then purified by a bag filter.

Our solutions monitor raceway gas and top gas for optimized pulverized coal injection.

Critical Control of Process Gas

A mix of fine coal powder and hot carrying air is inevitably creating carbon monoxide(CO). For the purpose of safety operation requests a continuous monitoring of oxygen(O₂) and trace carbon monoxide(CO) in each process of coal pulverization, transfer and storage.

FPI’s Solution

High – speed response (down to 1s) of the LGA analyzer highlights its reliability for safety control. The non – contact laser and sensor of the in – situ LGA combined with continuous purge results in virtually maintenance free.

In PCI raceways, LGA measures CO, O2, and H2 with ppb precision, optimizing injection for 150 kg/t coke replacement. Desulfurization H2S monitoring ensures 98% removal, cutting downtime by 20% and complying with ISO 11047 for BF gas analysis.

Our methodical approach drives success

Analyze raceway gas flows and top gas composition to identify injection imbalances.

Adapt LGA for tuyere or top gas ports, with ATEX certification and DCS linkage.

Install systems in 3-5 weeks with no interruption, including H2 calibration and training.

Supply 24/7 remote monitoring, yearly upgrades, and 2-year warranty for 99% reliability.

FPI excels in coal injection by refining raceway precision and desulfurization efficiency.

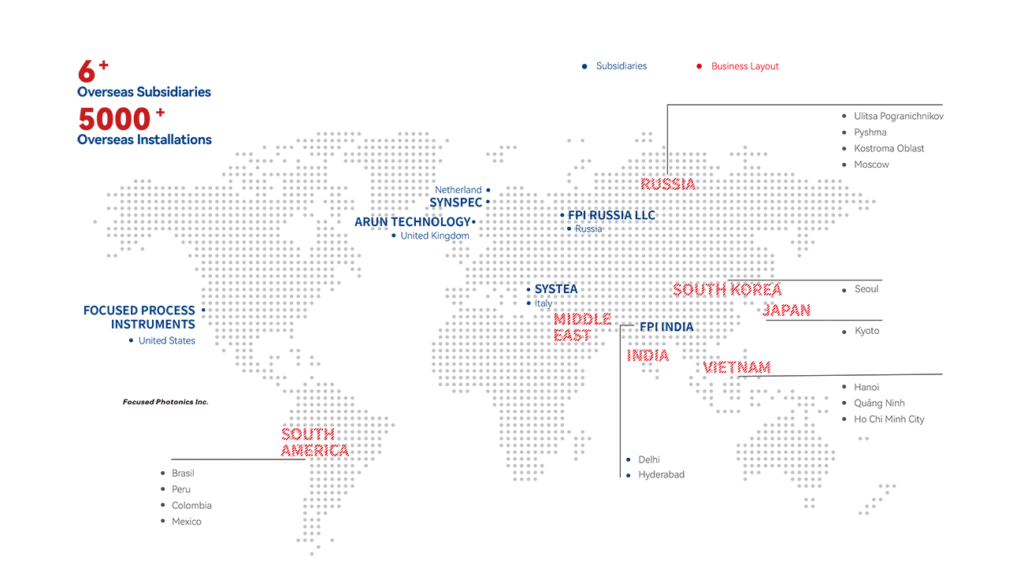

Additional metrics: 20+ years in gas analytics, 95% customer satisfaction, equipped 80+ PCI systems globally, in-situ laser for high-velocity streams.