Gas Chromatography Analyzers

As a leader in analytical instrumentation, FPI delivers reliable process-gas chromatograph analyzers that outperform competitors in speed and durability.

What is Gas Chromatography? Principles and Applications in Industrial Processes

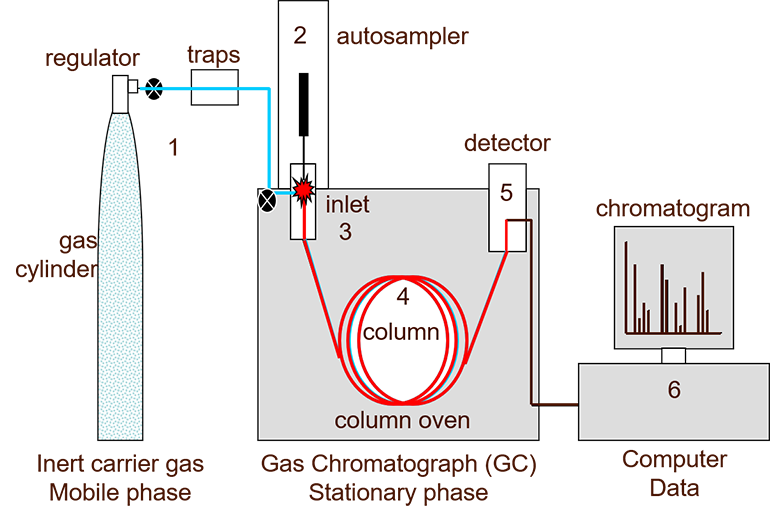

Gas Chromatography (GC) is a powerful analytical technique used to separate, identify, and quantify volatile compounds in gas mixtures, making it indispensable for industrial process monitoring. Unlike traditional lab-based methods, online gas chromatography analyzers enable continuous, real-time analysis directly at the process line, providing immediate insights for optimization and control. At its core, GC relies on the differential partitioning of sample components between a mobile phase (carrier gas) and a stationary phase (column coating), allowing for precise separation based on physical and chemical properties.

Read MoreLess

Core Principles of Gas Chromatography

- Sample Introduction and Vaporization: The process begins with injecting a gas or vaporized liquid sample into the system. In industrial process gas chromatographs, automated injectors ensure consistent sampling from streams like natural gas or refinery effluents, minimizing human error. FPI’s ProGC series features heated injectors to handle high-boiling hydrocarbons without condensation, ensuring reliable hydrocarbon analyzer performance.

- Separation Mechanism: The sample is carried by an inert gas (e.g., helium or nitrogen) through a chromatographic column—either packed (for high-capacity separations) or capillary (for high-resolution). Components separate based on boiling points, polarity, and interactions with the stationary phase. Temperature programming ramps up heat to elute compounds efficiently, reducing analysis time. In online GC analyzers, multi-column setups (e.g., heart-cutting techniques) allow for complex mixtures, detecting trace impurities down to parts-per-billion (ppb) levels—critical for compliance with standards like ASTM D1945.

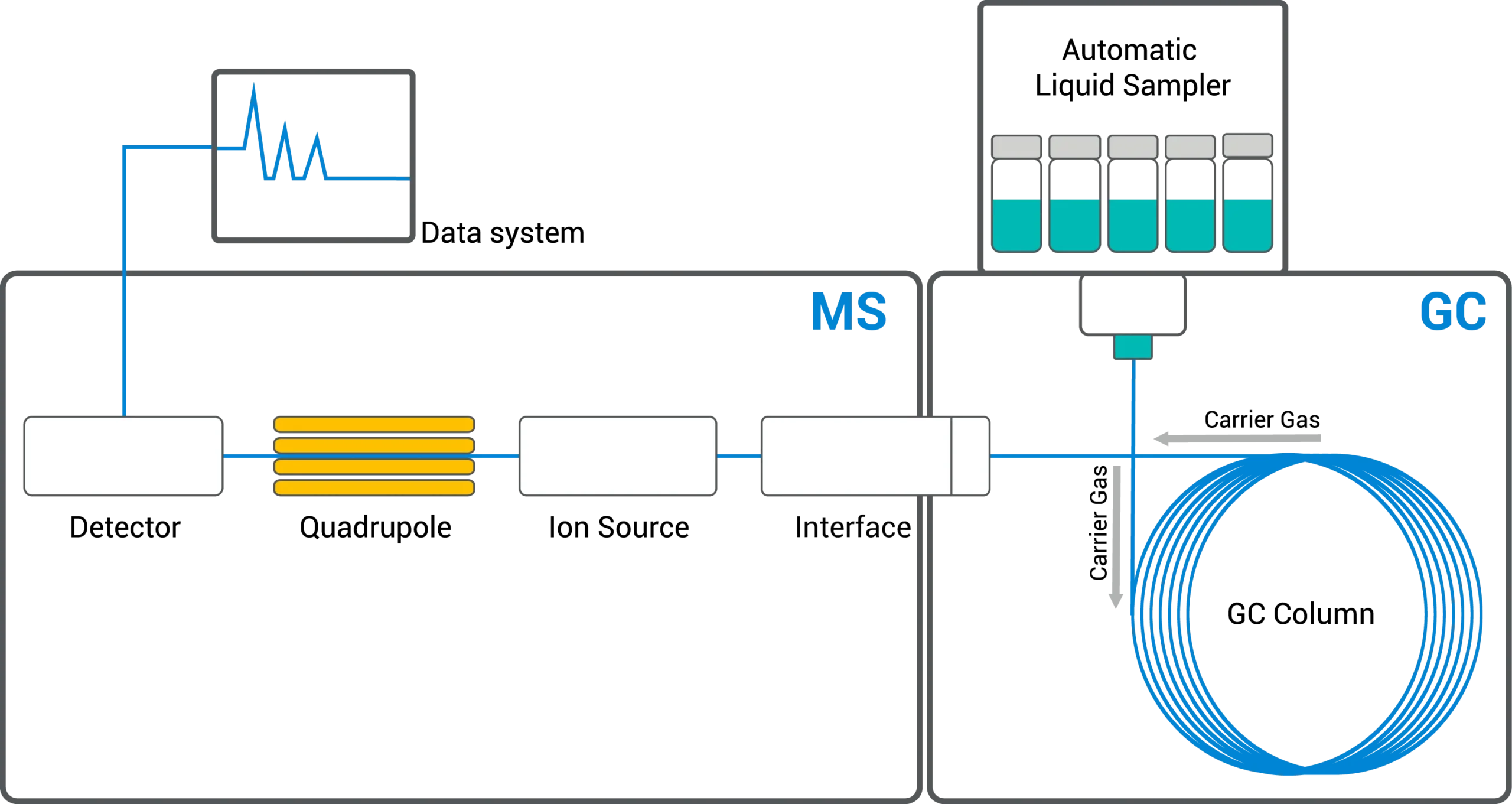

- Detection and Quantification: Detectors such as Thermal Conductivity Detectors (TCD) for permanent gases or Flame Ionization Detectors (FID) for organics measure eluted peaks. Signal processing software integrates peak areas for concentration calculations. Advanced systems incorporate Mass Spectrometry (GC-MS) for compound identification. FPI integrates proprietary photonics technology in our industrial online GC analyzers, enhancing sensitivity and selectivity beyond standard detectors, reducing false positives in noisy industrial environments.

- Key Parameters and Optimization: Factors like column length, flow rate, and oven temperature influence resolution and speed. Cycle times in lab GC can exceed hours, but process-gas chromatograph analyzers achieve minutes through optimized designs, enabling proactive process adjustments.

Industrial Applications and Advantages

GC excels in sectors requiring precise gas composition data:

- Petrochemical and Refining: Monitoring feedstock purity and product quality to prevent catalyst poisoning.

- Natural Gas Processing: Measuring BTU content, sulfur compounds, and hydrocarbons for pipeline safety.

- Environmental Monitoring: Detecting volatile organic compounds (VOCs) and emissions in compliance with EPA regulations.

- Pharmaceutical and Power Generation: Ensuring solvent purity or optimizing combustion efficiency.

The shift to online gas chromatography from offline methods offers transformative benefits: real-time data reduces downtime, improves yield (up to 15-20% in FPI client cases), and lowers costs by minimizing lab transport. However, challenges like column degradation in harsh conditions are addressed in FPI’s robust, explosion-proof designs.

Compared to alternatives like Infrared Spectroscopy (less selective for complex mixtures) or Mass Spectrometry (higher cost for standalone use), GC provides a balanced, cost-effective solution for real-time gas chromatography monitoring. FPI’s innovations, such as AI-driven diagnostics, further elevate performance, making our systems a superior choice over competitors like Agilent or Shimadzu for demanding industrial applications.

Ready to apply these principles? Explore how FPI’s ProGC series brings them to life.

Applications of FPI’s Gas Chromatography Solutions

FPI’s Online Gas Chromatographs deliver precise, real-time gas composition data across critical industries, enabling process optimization, regulatory compliance, and operational efficiency. From petrochemical purity to environmental monitoring, our Process Gas Chromatograph Hydrocarbon Analyzers drive measurable results.

Monitor feedstock and product purity with process-gas chromatograph analyzers to prevent catalyst poisoning and ensure quality. Real-time analysis optimizes yield and reduces waste, with clients reporting up to 15% efficiency gains.

Lorem ipsum dolor sit amet, consectetur adipisi cing elit, sed do eius mod tempor incididunt ut labore et dolore magna aliqua.

Optimize combustion efficiency in boilers and turbines by analyzing fuel gas composition, reducing emissions and operational costs.

erify solvent purity in production lines, ensuring product safety and regulatory adherence with high-sensitivity Process Gas Chromatographs.

By integrating FPI’s real-time gas chromatography monitoring, industries achieve enhanced productivity, safety, and sustainability, backed by proven results like reduced regulatory fines and improved process control.

Why FPI Excels in Process Gas Chromatography

Building on the principles of gas chromatography, FPI (Focused Photonics Inc.) delivers cutting-edge Process Gas Chromatographs and Online Gas Chromatography Analyzers that redefine industrial process monitoring. With over two decades of expertise in photonics and analytical technology, FPI provides innovative, reliable solutions tailored to meet the demands of complex industrial environments.

Stream Foundations: Unpacking FPI's Chromatography Detection

FPI’s systems trace gaseous signals through layered precision:

- Sample Admission: Multi-valve injection captures streams, minimizing loss with heated lines.

- Separation Synergy: Program-controlled columns partition components, oven ramping 1-50°C/min.

- Detection Delivery: FID/TCD quantifies peaks, AI deconvolving overlaps.

- Insight Integration: Software logs diagnostics, exporting via Ethernet for SCADA.

This chromatographic conduit, depicted in our column schematics, ensures vigilant streams.

Gas Chromatography Techniques Table: FPI’s Detection Diversity

| Technique | Components | Sensitivity | Deployment Fit | FPI Enhancement |

|---|---|---|---|---|

| Column Cutting | C1-C10 Hydrocarbons | 0.01% | Refineries | 16-channel multiplexing |

| Solid-State Oven | Gases (H2/CO) | ±0.01°C | Steel Mills | Drift-free temperature |

| FID/TCD Detection | Volatiles | 10 ppb | Chemical Plants | Dual-mode for selectivity |

| Modular Injection | Multi-Stream | <10s Lag | Power Gasification | Low-dead-volume valves |

FPI’s chromatographs channel 2025’s multi-stream imperatives.

Process Catalysts: Broader Impacts of FPI Chromatography

FPI chromatographs catalyze efficiency: In refineries, they trim 15% off-spec; in mills, recover 12% gases. With open protocols and low-SWaP, our systems foster digital twins, refining 25% of process indices for sustainable energy.

Stream Queries: Six Chromatography Answers

How does ProGC-3600 minimize sampling hysteresis in refineries?

Near-point installation with heated lines cuts lag to <10s, per ASTM D1945.

What oven precision aids gas resolution in -30°C environments?

Solid-state control holds ±0.01°C, enabling 0.01% hydrocarbon separation.

How does FID/TCD dual detection enhance volatile selectivity?

FID for organics, TCD for inerts, with AI deconvolution for <1% overlap.

Can FPI chromatographs integrate with refinery SCADA for alerts?

Ethernet/Modbus streams peaks to PLCs, triggering 18% faster adjustments.

What calibration meets ISO 6974 for process gas analysis?

Carrier gas standards yield <0.5% bias for H2/CO, with auto-diagnostics.

How do FPI systems endure corrosive steel mill gases?

ATEX-rated enclosures with SS316L valves sustain <2% drift in H2S, per GB/T 13611.

Request Callback

If you have any questions concerning our services, please fill out the contact form below.