Water Environment

Focused Photonics Inc. (FPI) protects aquatic ecosystems with its precision Water Environment Monitoring Systems, delivering real-time analysis of COD, ammonia nitrogen, total phosphorus, total nitrogen, heavy metals, and flow in rivers, wastewater, and drinking sources. Our SIA and WOA series integrate UV absorbance, electrochemical, and ion-selective technologies for compliance with EPA, GB 3838-2002, and EU WFD standards.

Aquatic Audit: Principles of Water Environment Detection

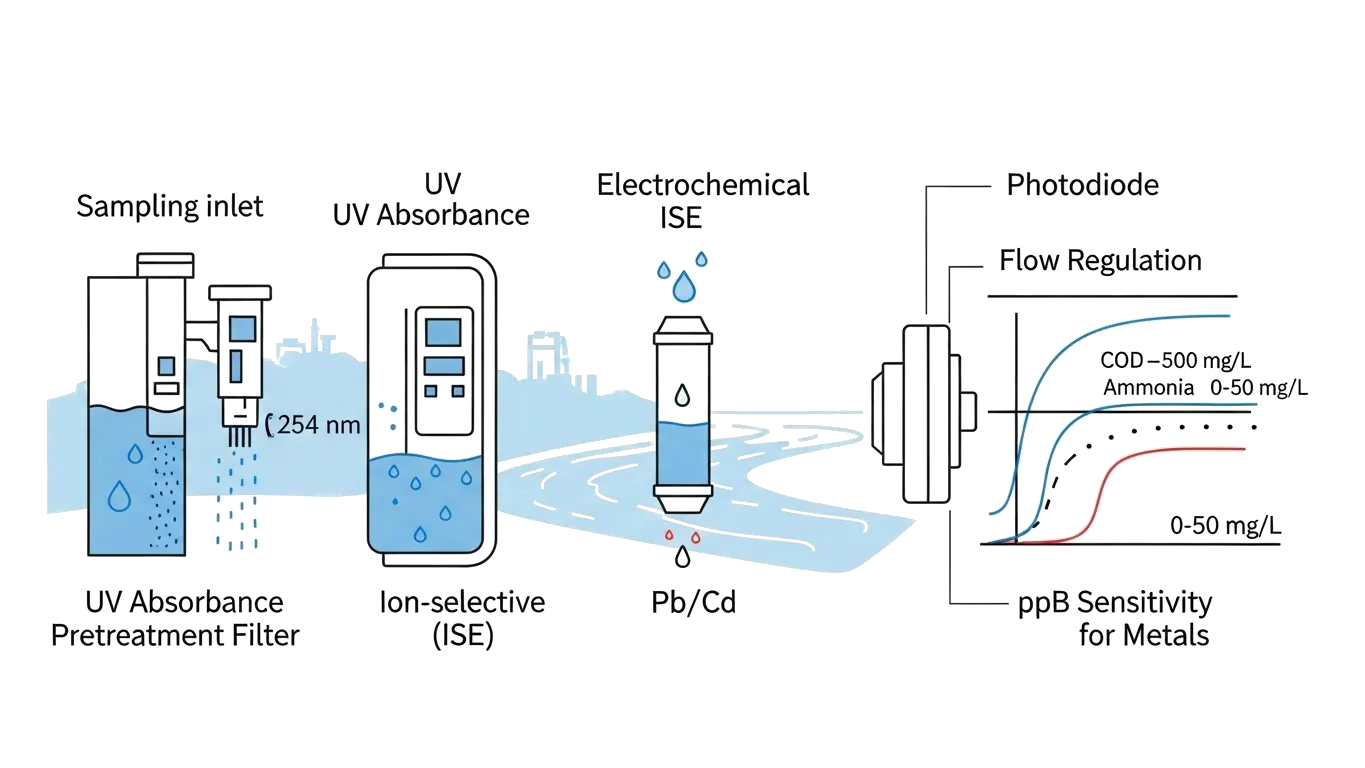

Water environment monitoring employs optical, electrochemical, and ion-selective techniques to quantify pollutants by measuring absorbance, potential, and ion binding. FPI’s systems utilize UV absorbance at 254 nm for COD (0-1000 mg/L, ±0.1 mg/L), electrochemical ISE for ammonia nitrogen (0-50 mg/L, ±0.05 mg/L) and pH (0-14, ±0.01), and flow-compensated sensors for total phosphorus/TP (0-10 mg/L, ±0.1 mg/L) and heavy metals (Pb/Cd/Hg, 0-1 mg/L, ±0.01 mg/L), achieving sensitivities per GB 3838-2002.

Read MoreLess

This methodology, evolved from titration standards since the 1970s, integrates pretreatment for turbidity up to 500 NTU and AI for speciation. FPI refines it with drift-free optics and temperature compensation (0-60°C), ensuring <1% uncertainty per ISO 17294. In 2025’s smart water era, our networks fuse in-situ sensors with satellite hydrology data, distinguishing point-source vs. diffuse pollution to inform EU WFD reporting and SDG 6 targets.

FPI Water Environment Systems in Ecosystem Protection

FPI's monitors secure 5,000+ aquatic sites, with 1,200+ units deployed annually, informing policies from basin restoration to urban discharge control.

SIA-3000 tracks COD/ammonia in Yangtze tributaries, reducing nutrient loads by 22% through targeted runoff management, per EU WFD 2000/60/EC.

SIA-3000 COD optimizes aeration in Shanghai plants, saving 18% energy while meeting GB 18918-2002 Class 1A standards for ammonia/TP discharge.

WOA-100 ensures heavy metal limits in reservoirs, cutting violations by 35% via real-time Pb/Hg alerts, aligned with WHO drinking guidelines.

SIA-3000 monitors As/Cu in farms, boosting shrimp yields by 20% through effluent control in saline waters.

These deployments, enriched by FPI’s open APIs, have informed 6+ national water policies, advancing SDG 6 clean water access.

FPI's Aquatic Vigilance: Sustaining Purity in Flows

With 22 years of sensor innovation, 888+ patents, and ISO 17025 certifications, FPI's systems prioritize durability and insight, offering 20% higher resolution than legacy networks.

Flow Foundations: Unpacking FPI's Water Detection

FPI’s systems trace aquatic signals through layered precision:

- Sample Acquisition: Pretreatment manifolds filter particulates, regulating flow (0-10 m³/h) for representative intake.

- Sensing Synergy: UV/electrochemical/ISE modules quantify parameters, cross-verified for turbidity compensation.

- Data Refinement: AI deconvolves spectra, outputting trends via MQTT for SCADA integration.

- Insight Delivery: Dashboards flag exceedances, generating reports for WFD compliance.

This fluid framework, depicted in our sensor schematics, ensures vigilant purity.

Water Environment Techniques Table: FPI’s Detection Diversity

| Technique | Parameters | Sensitivity | Deployment Fit | FPI Enhancement |

|---|---|---|---|---|

| UV Absorbance | COD | 0.1 mg/L | Wastewater | Dual-wavelength turbidity correction |

| Electrochemical ISE | Ammonia, pH | 0.05 mg/L | Rivers | Temperature-compensated electrodes |

| Flow-Compensated | TP/TN, Flow | 0.1 mg/L | Drinking | Integrated sensors for load accuracy |

| Ion-Selective | Heavy Metals (Pb, Cd) | 0.01 mg/L | Aquaculture | Selective membranes for multi-ion |

FPI’s toolkit flows with 2025’s multi-parameter imperatives.

Ecosystem Catalysts: Broader Impacts of FPI Monitoring

FPI systems catalyze restoration: In basins, they decouple 20% nutrient yields from pollution; in treatment, predictive alerts avert USD 180K fines. With low-SWaP designs and open APIs, our networks foster collaborative governance, refining 25% of local quality indices for SDG 6.

Aquatic Queries: Six Water Environment Answers

How do FPI systems ensure accuracy in turbid industrial discharges?

Ultrasonic pretreatment and dual-UV correction maintain <1.5% error in 600 NTU COD, per ISO 7027.

What AI role enhances FPI’s eutrophication forecasts in lakes?

Neural networks analyze TP/DO correlations, predicting blooms with 88% accuracy for proactive dosing.

How does SIA-3000 support emergency spill response at outfalls?

Portable ISE detects ammonia/heavy metals in 4 minutes, enabling EPA SPCC containment protocols.

How do FPI analyzers connect with urban SCADA for discharge control?

Modbus RTU streams COD/pH to PLCs, optimizing treatment for 18% chemical efficiencies.

What calibration upholds FPI compliance with GB 3838-2002 surface water standards?

NIST SRM 1640-based calibrations achieve <0.3 mg/L bias for Cd/Pb, per ISO 17294.

How do FPI probes endure saline estuary deployments?

Titanium casings and salinity-adjusted ISEs sustain <2% drift in 40 ppt, per ASTM D1141.

Request Callback

If you have any questions concerning our services, please fill out the contact form below.

.png)