Stack Emission Monitoring Systems

Focused Photonics Inc. (FPI) safeguards the planet with its robust Stack Emission Monitoring Systems, delivering continuous, compliant analysis of flue gases to curb industrial pollutants. Our CEMS platforms integrate extractive sampling, multi-gas detection, and data acquisition for real-time SO2, NOx, CO, and PM oversight, ensuring adherence to stringent regulations.

Emission Equilibrium: The Mechanics of Stack Monitoring

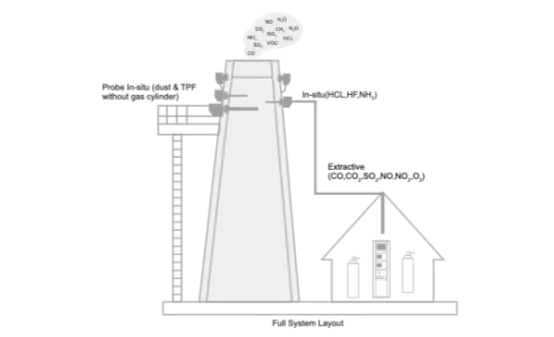

Stack emission monitoring employs continuous emission monitoring systems (CEMS) to extract, condition, and analyze flue gases from industrial stacks, quantifying pollutants via optical, electrochemical, or gravimetric methods. FPI’s systems draw heated samples through probes, cool/dry them to remove moisture, then route to analyzers: UV for SO2/NOx, IR for CO/CO2, beta attenuation for PM, and chemiluminescence for O2.

Read MoreLess

This holistic approach, codified in EPA Method 6C since the 1970s, now leverages multipoint averaging and predictive modeling for stack-wide profiling. FPI enhances reliability with heated umbilicals to prevent condensation and auto-zeroing for drift-free operation, achieving <2% uncertainty per EU IED standards. In 2025’s carbon-constrained era, our systems support CCUS validation by tracing CO2 plumes, minimizing false positives in variable flows and fostering proactive emission abatement.

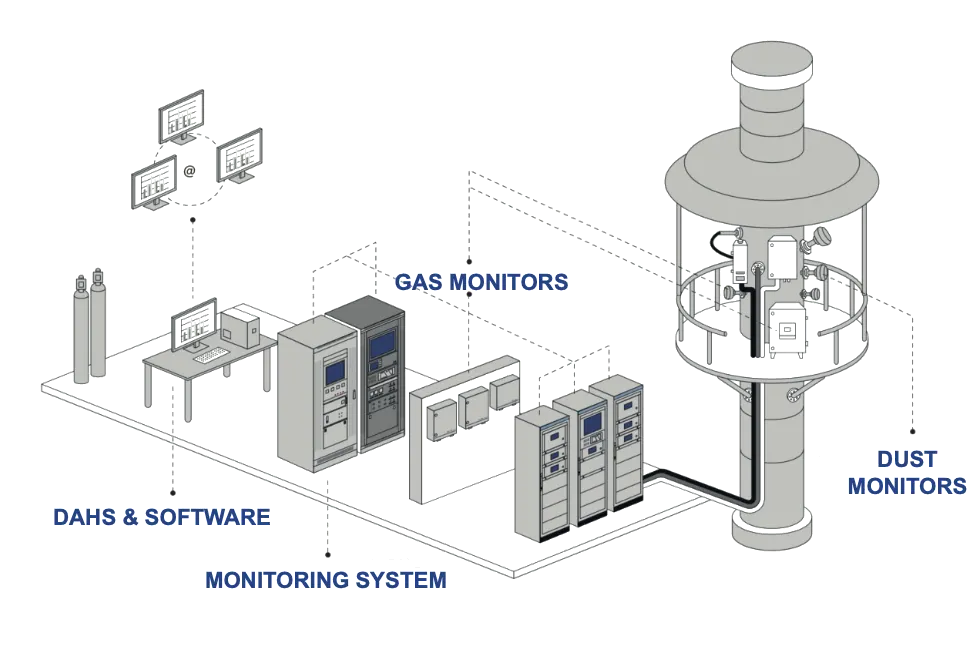

SYSTEM STRUCTURE OF FPI CEMS SERIES:

FPI CEMS provides application gas analysis solution, integrated with Particulate Monitoring Subsystem, TPF Monitoring Subsystem, Gaseous (Pollutant) Monitoring Subsystem, Data Acquisition and Processing Subsystem, covering all the indicators and parameters to meet different customers’ needs. Such systems are extensively installed in industrial boilers, indicators and other emission sources with real-time data uploaded to local authorities.

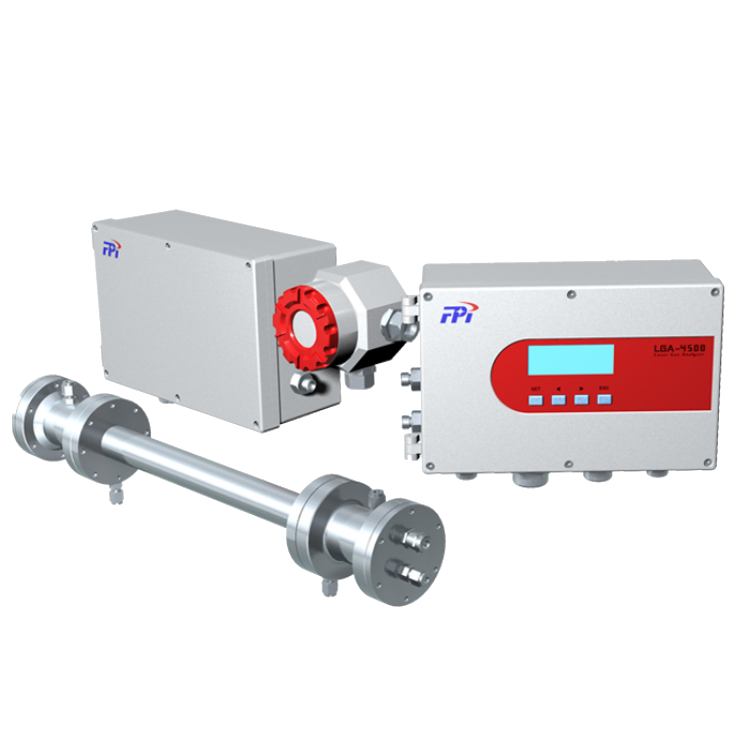

MONITORING COMPONENTS OF MODELS OF CEMS SERIES:

System Model | Components |

SO2, NOX, CO, CO2 | |

SO2, NOX, CO | |

HgT, Hg2+, Hg0 | |

Methane & Non-methane, THC, BTEX, Other organic compounds. | |

SO2, NOX, NH3, HCl, HF, CO, CO2, H2O | |

*Oxygen, particulate matter, humidity, temperature, pressure and flow rate are monitored via the optional module for all system. | |

Compliance Catalysts: FPI CEMS in Environmental Stewardship

FPI's stack monitors secure 7,000+ global installations, with 1,800+ units commissioned yearly, translating regulatory mandates into operational excellence.

CEMS-2000 tracks SO2/NOx in coal boilers, enabling SCR/SNCR tuning. A Huaneng plant deployment reduced NOx by 45%, aligning with China's 2025 ultra-low targets.

Multi-gas arrays monitor HCl/HF in flare stacks, per US EPA 40 CFR 60. In a Veolia incinerator, FPI's PM beta gauge ensured 99% uptime, averting fines exceeding USD 500K.

Real-time CO/PM profiling optimizes sinter belts, cutting fugitive dust. Baosteel's integration yielded 20% emission cuts, supporting EU BAT conclusions.

Portable CEMS variants audit ship exhausts under IMO MARPOL Annex VI, with NOx analyzers for selective catalytic reduction efficacy.

These enforcements, fortified by FPI’s DAHS for seamless reporting, have curbed 1.5 million tons of annual pollutants, advancing SDG 13 climate action.

FPI's Emission Excellence: Pioneering Compliant Horizons

With 22 years of environmental optics, 888+ patents, and EPA-certified validations, FPI's CEMS outshine conventional setups in accuracy and adaptability.

SYSTEM STRUCTURE OF FPI PARTICULATE & SOURCE ANALYSIS SYSTEM

FPI’s systems orchestrate emission oversight through integrated layers:

- Extraction Engine: Isokinetic probes draw representative flows, filtered for particulates.

- Conditioning Cascade: Thermoelectric dryers and particulate traps prepare gases for analysis.

- Detection Deployment: Parallel analyzers yield simultaneous readings, with multiplexer for stack profiling.

- Reporting Radiance: DAHS aggregates data, flagging violations via SMS/ERP alerts.

This vigilant vein, mapped in our CEMS schematic, upholds unyielding integrity.

CEMS Components Compared: FPI’s Integrated Insight

| Component | FPI Innovation | Measurement | Compliance Edge | Vs. Standard |

|---|---|---|---|---|

| Sampling Probe | Heated SS316L, auto-purge | Flow-balanced | <0.5% bias per EPA 1 | Adaptive vs. fixed-length |

| Gas Conditioner | Peltier dryer, Nafion scrubber | Moisture/PM removal | 95% efficiency | Integrated vs. separate units |

| SO2/NOx Analyzer | UV DOAS | 0-5000 ppm | <1% uncertainty | Cross-interference free |

| CO/CO2 Analyzer | NDIR | 0-50% | T90 <30s | Dual-beam stability |

| PM Monitor | Beta gauge | 0-500 mg/m³ | 24-hour averages | Continuous vs. manual |

FPI’s synergy suits 2025’s multi-pollutant mandates.

Emission Enablers: Strategic Gains from FPI Monitoring

FPI CEMS convert compliance to competitive edge: In cement, they optimize fuel blends for 15% CO2 cuts; in power, predictive alerts avert USD 100K downtime. With remote diagnostics and green optics, our systems champion fiscal prudence, yielding 25% ROI via fine avoidance and efficiency audits.

Vigilance Vault: Six Emission Essentials Explored

How do FPI CEMS adapt to variable stack velocities in wind-tunnel plants?

Dynamic isokinetic controls adjust probe angles via anemometer feedback, maintaining ±2% representativeness across 5-30 m/s flows.

What cybersecurity measures protect FPI DAHS from remote tampering?

End-to-end AES-256 encryption and role-based VPN access, compliant with NIST SP 800-53, safeguard data integrity in cloud-synced networks.

How can FPI systems support carbon credit verification under Article 6 of Paris Agreement?

Integrated CO2 flux modeling with isotopic tracers provides auditable baselines, streamlining MRV for voluntary markets.

In marine applications, how does FPI handle sulfur scrubber bypass detection?

Real-time SO2/CO2 ratio anomalies trigger alerts, with historical trending for MARPOL compliance audits.

What calibration traceability does FPI offer for international accreditation?

NIST-traceable standards via annual interlab comparisons, ensuring <3% deviation for ISO 17025 scopes.

How do FPI CEMS facilitate predictive maintenance for emission exceedances?

Machine learning on historical spectra forecasts analyzer drift, scheduling preemptive swaps to sustain 99% uptime.

Request Callback

If you have any questions concerning our services, please fill out the contact form below.