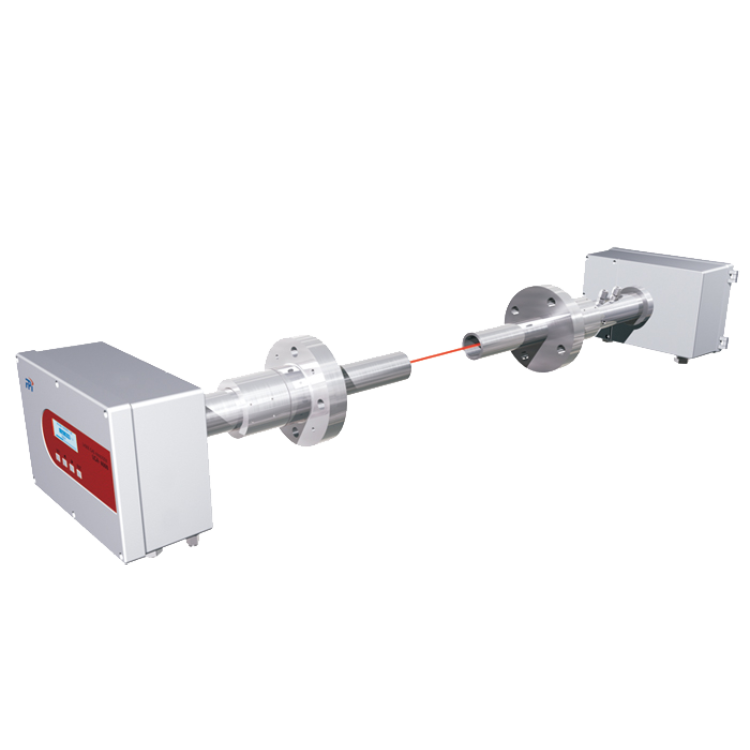

Industrial Process UV Analyzer

As a leading innovator in analytical instrumentation, Focused Photonics Inc. (FPI) offers advanced UV gas analyzers leveraging ultraviolet spectroscopy for precise, real-time gas detection in industrial processes. Our solutions excel in monitoring pollutants and process gases with high sensitivity and minimal interference, enabling enhanced efficiency, safety, and compliance.

What is UV Gas Analysis? Principles and Applications in Industrial Processes

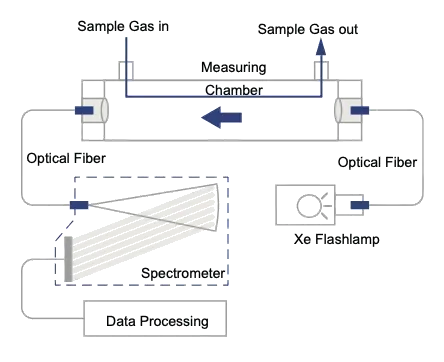

Harnessing the proven Lambert–Beer law, our UV gas spectroscopy system separates rapidly varying and slowly varying spectral components, with fast variations directly attributed to gas absorption. A high-stability ultraviolet light source is precisely focused and coupled into a fiber optic transmission pathway, guiding light into the gas cell. As the beam passes through, the target gas molecules selectively absorb characteristic wavelengths.

The transmitted light is then directed to a high-resolution spectrometer, where a precision diffraction grating disperses the signal. A sensitive array detector captures and converts the dispersed light into accurate electrical signals, producing a continuous absorption spectrum of the gas.

Read MoreLess

This advanced fiber optic absorption spectroscopy solution delivers real-time, high-sensitivity, and high-accuracy gas measurements. Its robust design ensures long-term stability and repeatability, making it ideally suited for environmental monitoring, industrial process control, and scientific research applications. By combining superior optical engineering with powerful data acquisition, the system provides unmatched performance for detecting and quantifying trace gases in complex environments.

Applications of FPI’s UV Gas Analyzer Solutions

FPI’s UV gas analyzers deliver reliable, on-site measurements across industries, supporting over 10,000 installations with annual sales surpassing 2,000 units. Our systems integrate seamlessly into processes, providing data for optimization and compliance.

Monitoring VOCs, benzene, and sulfur compounds in refining processes to ensure product quality and reduce emissions. Case Study: In Sinopec facilities, FPI analyzers improved VOC control, cutting regulatory risks by 18%.

Ambient air quality stations track O3, CO, and PM precursors, while water applications detect COD and nutrients via UV absorption.

Real-time flue gas analysis for SO2 and NOx, aiding ultra-low emission standards in coal-fired plants and cement kilns.

Ensuring purity in process gases and detecting contaminants, with trends toward AI-integrated workflows for faster analysis in 2025.

Clients achieve up to 20% efficiency gains, with FPI’s solutions excelling in high-humidity and dusty environments.

Why FPI Excels in UV Spectroscopy Solutions

With 22 years of expertise, 888+ patents, and national recognitions like the China Patent Gold Award, FPI pioneers autonomous UV spectroscopy technology. Our analyzers surpass competitors like Thermo Fisher, Agilent, and Horiba in cost-effectiveness and field durability.

Stream Foundations: Unpacking FPI's UV Detection

FPI’s analyzers trace gaseous signals through layered precision:

- UV Illumination: Broadband lamps flood sample path, capturing full-spectrum absorption.

- Path Amplification: Multipass cells extend interaction, boosting signal-to-noise.

- Differential Measurement: Spectrometers subtract reference, isolating target bands.

- Insight Integration: Software fits Voigt profiles, exporting via RS485 for SCADA.

This UV conduit, depicted in our multipass schematics, ensures vigilant streams.

UV Analyzer Techniques Table: FPI’s Detection Diversity

| Technique | Gases | Sensitivity | Deployment Fit | FPI Enhancement |

|---|---|---|---|---|

| UV-DOAS | SO2, H2S | 0.5 ppm | Scrubbers | Broadband rejection of H2O |

| Multipass Absorption | NH3, Cl2 | 0.05 ppm | Reactors | Teflon-coated paths |

| AI Baseline Subtraction | Multi-gas | <0.5% Drift | Stacks | Pressure-scanned fitting |

| Remote Diagnostics | All | <1 min Alert | Plants | Ethernet self-test |

FPI’s UVs illuminate 2025’s corrosive imperatives.

Process Catalysts: Broader Impacts of FPI UV Analyzers

FPI UV analyzers catalyze safety: In scrubbers, they trim 15% SO2 waste; in reactors, cut 18% NH3 risks. With open protocols and low-SWaP, our systems foster emission dashboards, refining 25% of process indices for sustainable chemistry.

Stream Queries: Six UV Answers

How does LGA-UV achieve ppm accuracy in wet scrubbers?

Multipass (50m path) and Teflon coatings resist H2O interference, with <0.5% drift per ASTM D6348.

What broadband role aids FPI’s multi-gas tracing in stacks?

200-400 nm coverage resolves SO2/NH3 without filters, with 90% cross-rejection.

How does UV minimize maintenance in 100°C exhausts?

Non-contact flanges and sealed optics reduce cleanings by 70%, per ISO 6974.

Can FPI analyzers integrate with chemical SCADA for dosing?

RS485 streams H2S/Cl2 to PLCs, optimizing 18% faster adjustments.

What calibration meets GB/T 18204 for industrial UV gas?

UV standards yield <0.3 ppm bias for NH3, with auto-baseline.

How do FPI UVs endure corrosive chlorine streams?

SS316L housings and humidity compensation sustain <1% error in 50 ppm Cl2, per OSHA 1910.1000.

Request Callback

If you have any questions concerning our services, please fill out the contact form below.