Laser Gas Analyzer

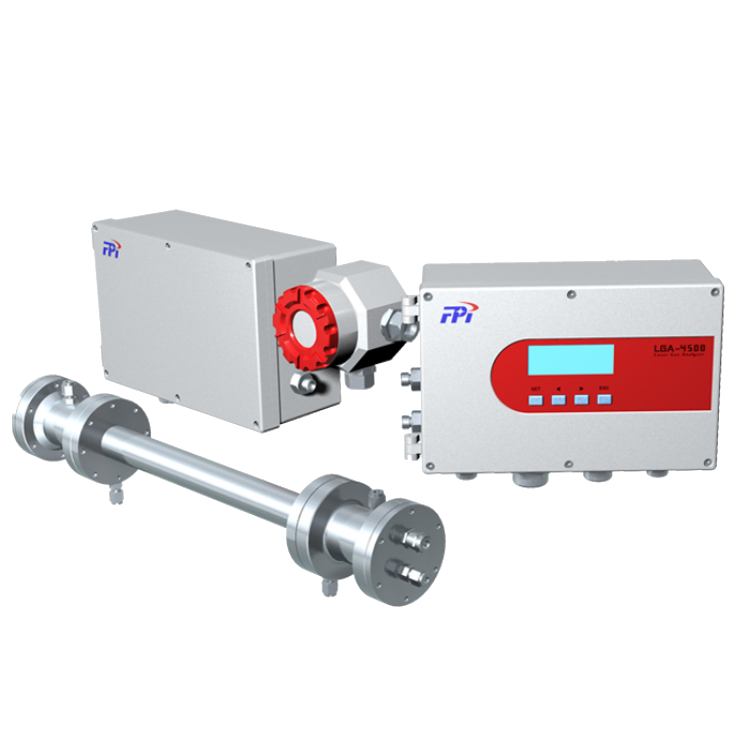

As a global leader in high-end analytical instrumentation, Focused Photonics Inc. (FPI) delivers innovative laser gas analyzers based on Tunable Diode Laser Absorption Spectroscopy (TDLAS) and other advanced laser technologies.

What is Laser Gas Analysis? Principles and Applications in Industrial Processes

Utilizing proprietary technologies of Tunable Diode Laser Absorption Spectroscopy (TDLAS), FPl delivers the LGA system to satisfy in-situ measurements with high accuracy, fast response, strong reliability and virtually maintenance free.

The LGA system is applicable to almost all industrial process, especially well proven in harsh conditions in combination of high temperature, pressure, dust, corrosives and contaminants.Leveraging an installed base of over 8.000 units, the LGA system has been extensively used for combustion and safety control, process optimization, energy recovery, scientific research as well as environment monitoring. To date, these units have been employed in metallurgy, refinery, oil refinery, natural gas, power plant, waste incineration, cement and other situations where gas measurement is needed.

Read MoreLess

How Does Laser Gas Analyzer Work?

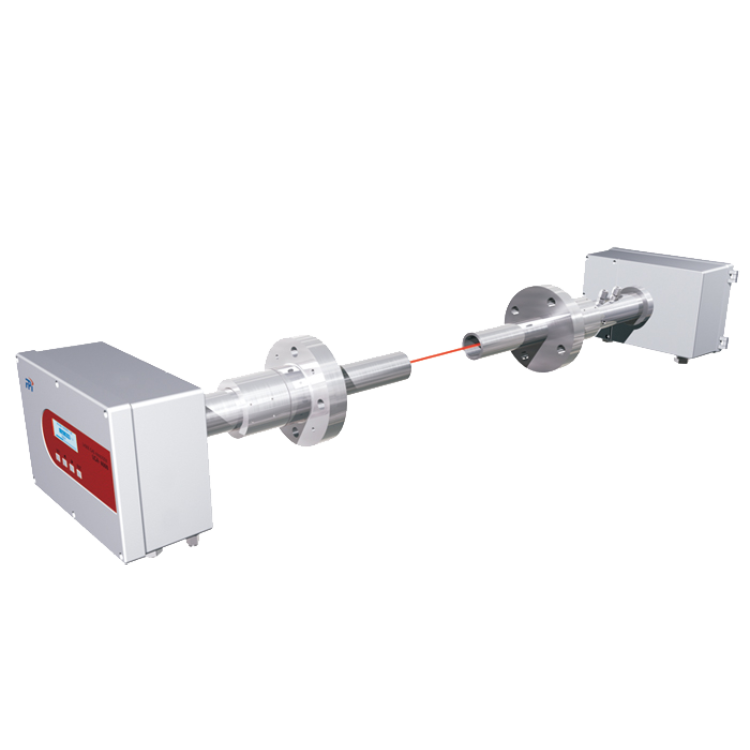

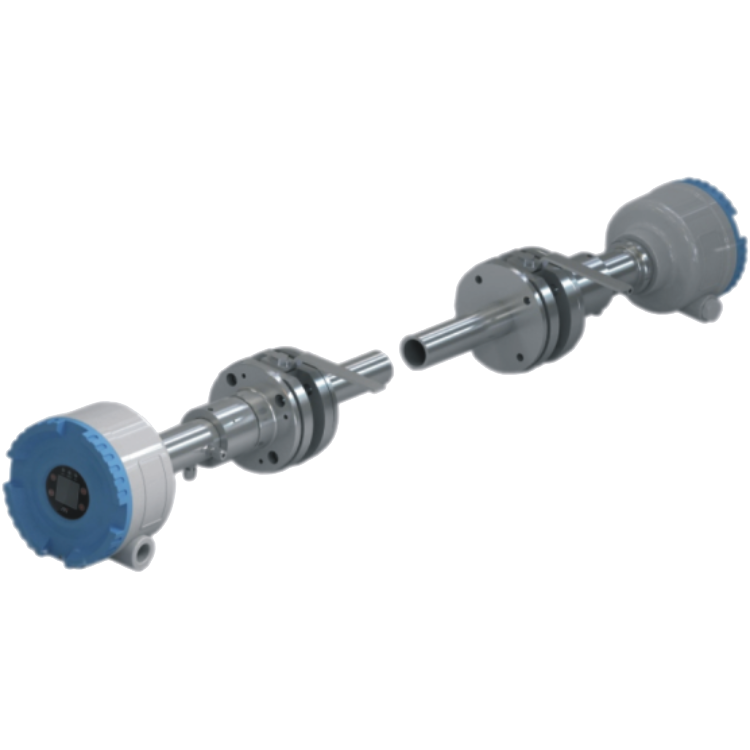

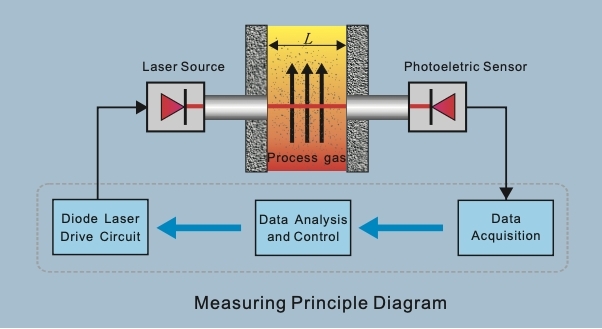

The laser beam from the transmitter unit passes across the stack or duct work and is absorbed by the measured gas. The attenuated light is then detected by the photoelectric sensor in the receiver unit, and the resulting signal is sent back to the transmitter unit and analyzed to yield gas concentration.

What Is The Difference Between TDLAS And Conventional Online Monitoring System?

Item | TDLAS Laser Analyzer | Conventional Online Analysis |

Adaptability | Application to high temperature, pressure, moisture, dust density and corrosion. | Applicable to constant temperature, pressure and dust free |

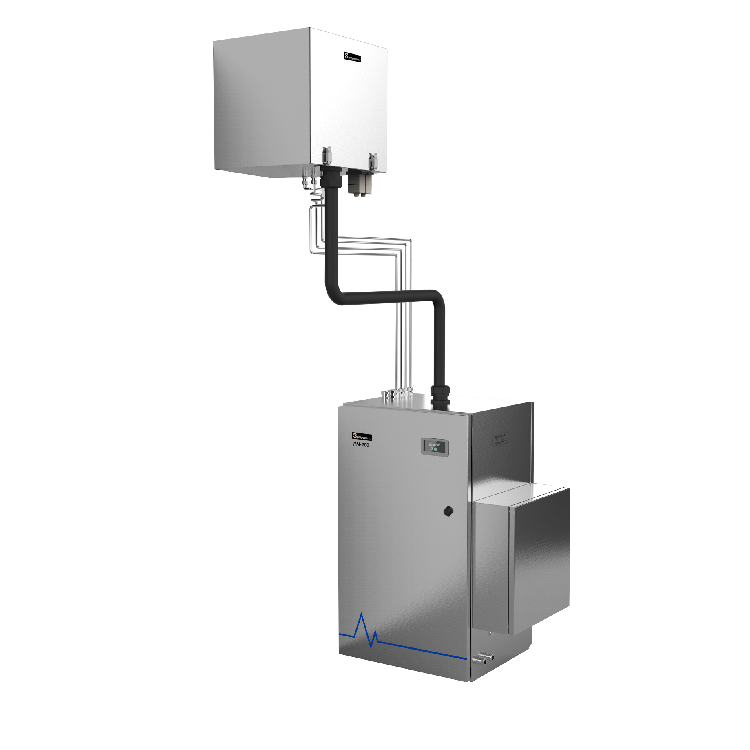

Measurement | In-situ, continuous/real-time measurement; sample gas evacuation free | With sample conditioning system, discontinuous measurement. |

Response Time | Fast, only limited by electronics response, less than 1s | Slow, limited by gas sampling, transport, and instrument electronics response 20+sec |

Accuracy | Average concentration along the optical path; no cross interference from other gas species, dust, and gas parameter fluctuations. | Gas concentration at the tip of the sampling probe only, affected by gas influence and absorption, and leaked during gas sampling and transport; cross interference from other gas species, dust, and gas parameter fluctuations; gas information lost due to dissolution, absorption, and leakage. |

Reliability | No moving parts, highly reliable | Many moving parts, low reliability |

Calibration &Maintenance | Calibration:<2times/year Maintenance: <2times/year | Calibration: 2-3times/month Maintenance: frequent |

Operation Costs | No spare parts, only cost of electricity | Lots of spare parts, around 20% of the equipment cost per year. |

Features Of FPI TDLAS Series Laser Gas Analyzer

No Cross Interference

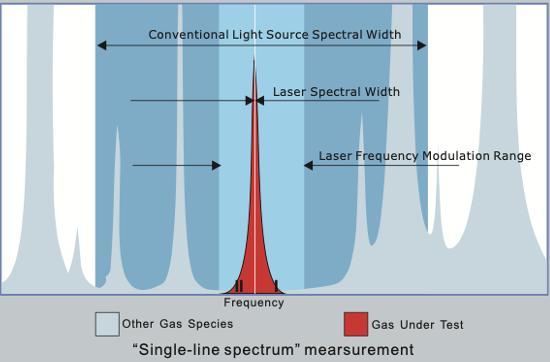

The laser spectrum features excellent monochromaticity with spectral width down to 0.00lnm, which is much narrower than spectral width of other light sources. By utilizing the ‘Single-line’ spectroscopy, a well-targeted laser spectrum can be sorted out to cover only the measuring gas without overlapping spectrum of all background gases.

No Effects from Dust, Moisture and Window Contamination

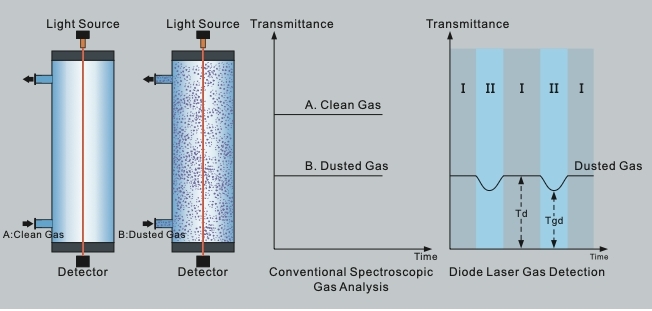

TDLAS gas analyzers use a laser spectral scanning technique. The unit periodically scans the gas under test with a modulation frequency range large than the gas absorption spectral line-width such that, within one scan period, there are two distinctive areas. Area I is unaffected by the gas absorption and gives Td, whereas Area II is effected and gives Tgd.

The transmittance of the gas under test is then calculated accurately by Tg=Tgd/Td. The interference from dust and optical window contamination is therefore, automatically screened out.

Automatic Temperature & Pressure Compensation

When gas temperature and pressure under measurement changes, the width and height of the absorption waveform change, which effects the accuracy of the measurement. By having 4~20mA process temperature and pressure input, the LGA laser gas analyzer automatically compensates for them with a proprietary algorithm to ensure measurement accuracy.

Applications of FPI’s Laser Gas Analyzer Solutions

FPI’s laser gas analyzers are deployed across critical sectors, delivering precise data that drives operational excellence and regulatory compliance. With over 8,000 global installations and annual sales exceeding 2,000 units, our systems address diverse challenges from high-temperature processes to remote monitoring.

In refining and natural gas processing, FPI analyzers monitor hydrocarbons, H2S, and NH3 in sulfur recovery units and cracking furnaces. Case Study: At Sinopec, our LGA-4100 reduced downtime by 15% through real-time leak detection, aligning with increasing demand for methane monitoring in gas infrastructure.

For blast furnaces and coke ovens, systems track CO, O2, and H2 to optimize combustion and recover energy, cutting emissions and costs in coal chemical processes.

Flue gas analysis ensures ultra-low emissions, with explosion-proof designs handling high-pressure environments. Integration with CEMS supports ESG goals in thermal power and waste incineration.

Trace gas detection in chlorination and semiconductor fabs prevents contamination, with portable units for emergency response.

Emerging Trends: Carbon Capture and Smart Monitoring

As industries adopt carbon capture systems, FPI analyzers measure CO2 and impurities with ppb sensitivity. Smart integrations enable predictive analytics, reflecting 2025 trends in IoT-enabled environmental monitoring.

Clients report up to 25% efficiency gains and compliance with global standards like US EPA methods.

Why FPI Excels in Laser Gas Analyzer

Backed by 22 years of R&D, 888+ patents, and 11% revenue investment in innovation, FPI overcomes core technology challenges to offer autonomous, high-performance solutions. Our analyzers outperform competitors like ABB and Siemens in cost-effectiveness and adaptability.

Stream Foundations: Unpacking FPI's TDLAS Detection

FPI’s analyzers trace gaseous signals through layered precision:

- Laser Tuning: Diodes scan absorption lines, selecting target wavelengths for specificity.

- Path Amplification: Herriott cells extend interaction, enhancing signal-to-noise.

- Absorption Measurement: Photodiodes capture attenuation, AI inverting Beer’s law.

- Insight Integration: Software compensates for pressure, exporting via Ethernet for SCADA.

This laser conduit, depicted in our multipass schematics, ensures vigilant streams.

TDLAS Techniques Table: FPI’s Detection Diversity

| Technique | Gases | Sensitivity | Deployment Fit | FPI Enhancement |

|---|---|---|---|---|

| Multipass TDLAS | CO, NH3 | 0.1 ppm | Pipelines | Patented flange for turbulence |

| Isotopic Tuning | CO2, CH4 | <0.5‰ δ13C | Furnaces | Dual-beam for attribution |

| Pressure Compensation | H2O | ±0.1% | Exhausts | Real-time barometric correction |

| AI Inversion | Multi-gas | <0.5% Drift | Reactors | Baseline auto-correction |

FPI’s lasers illuminate 2025’s multi-gas imperatives.

Process Catalysts: Broader Impacts of FPI TDLAS

FPI TDLAS catalyzes control: In pipelines, it trims 15% NH3 waste; in furnaces, cuts 20% CO emissions. With open protocols and low-SWaP, our systems foster digital twins, refining 25% of process indices for sustainable energy.

Stream Queries: Six TDLAS Answers

How does LGA-4000 achieve ppm accuracy in turbulent pipelines?

Multipass cells (100m path) amplify signals, with AI turbulence compensation for <0.5% drift, per ASTM D6348.

What isotopic role aids FPI’s leak source attribution in refineries?

Dual-beam δ13C resolves biogenic vs. fossil CO2, with 90% attribution accuracy for LDAR compliance.

How does TDLAS minimize maintenance in 1400°C furnaces?

Water-cooled flanges and non-contact design reduce interventions by 70%, per ISO 6974.

Can FPI analyzers integrate with process SCADA for alarms?

Ethernet/Modbus streams NH3/CO to PLCs, triggering 18% faster shutdowns.

What calibration meets GB/T 18204 for industrial gas analysis?

Carrier gas standards yield <0.3 ppm bias for H2O, with auto-diagnostics.

How do FPI TDLAS endure corrosive syngas streams?

SS316L optics and pressure compensation sustain <1% error in 50% H2, per API 618.

Request Callback

If you have any questions concerning our services, please fill out the contact form below.