Hot rolling starts from the process of feeding slabs, blooms or billets into a reheating furnace and heating to a high temperature between 900-1400 ‘C by burners that use fuels such as by-product gas or LNG. Most of the reheating furnace is controlled using latest on-line instrumentation for least possible fuel consumption and highest productivity.

Our solutions integrate precise gas analysis and temperature monitoring for reheating furnaces in hot rolling processes.

FPI’s cross-duct LGA measures average gas concentration along the laser beam path, resulting in much less effect from gas turbulence and gas sources change. The real-time precise measurement of combustion process helps reduce energy use by 5% and reduce burning loss by 10-20%.

The fine-tuned laser spectrum intentionally eliminates methane (CH4) absorption that is capable of detecting CO content with no interference in all combustible gases, either coal, LNG or mixed gas. The flexibility of LGA optical length (0.5-20m) suits it perfectly for all types of reheating furnaces in any size. The heat-proof LGA enhanced with water cooling system stands well at the condition of high temperatures (up to 1400℃) both inside and outside the furnace.

FPI’s infrared thermography systems deliver non-contact temperature measurements up to 1400°C with ±2°C accuracy in reheating furnaces, mapping slab surfaces to detect hotspots and ensure uniform heating. Integrated with LGA gas data, these tools prevent over-burning, reducing scrap rates by 8-12% and improving rolling consistency in hot rolling lines.

FPI’s integrated LGA and thermography solutions feed combustion and temperature data to AI algorithms for predictive air-fuel adjustments, minimizing fuel waste and NOx emissions. This setup optimizes reheating cycles, achieving 15% lower CO2 output while maintaining throughput, tailored for slab and billet processing in steel mills.

FPI’s solutions for iron and steel metallurgy emphasize real-time combustion optimization in reheating furnaces to minimize energy loss and emissions during hot rolling. The LGA series offers cross-duct laser gas analysis for CO, O2, and H2, enabling accurate air-fuel ratio control. Combined with infrared thermography for slab temperature profiling, these tools integrate with DCS systems for automated adjustments, supporting low-NOx burners and productivity gains in steel production lines.

Our methodical approach drives success

Conduct on-site audits of furnace gas flows, temperature profiles, and fuel types to pinpoint combustion inefficiencies and energy losses.

Tailor LGA optical paths and thermography configurations to furnace dimensions and fuel mix, ensuring seamless DCS compatibility.

Install ATEX-certified systems in 4-6 weeks with minimal downtime, including operator training and initial calibration.

Offer 24/7 remote diagnostics, quarterly software updates, and 2-year warranty to sustain 99% uptime.

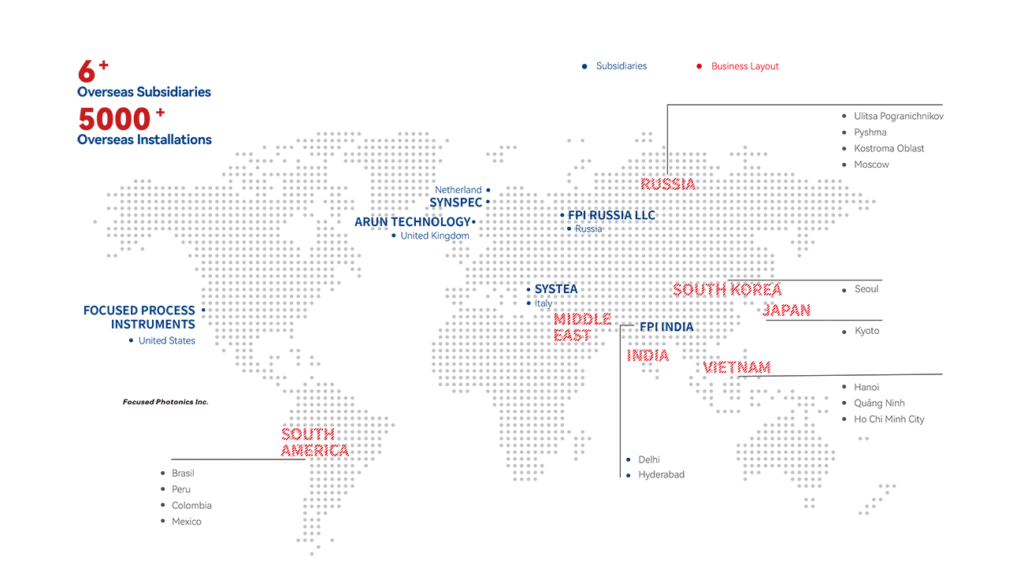

Additional metrics: 20+ years in industrial gas analytics, equipped 150+ steel mills globally, 96% customer satisfaction, laser technology for high-temperature precision.